Optimizing Your Processes: How Consulting Services Create Lasting Change

The goal of engaging with a process optimization consulting service is to drive lasting change. This won’t happen if the measures implemented by the organization

The goal of engaging with a process optimization consulting service is to drive lasting change. This won’t happen if the measures implemented by the organization

Running a manufacturing plant is difficult. You must manage multiple stakeholders, drive continual improvement while maintaining safety standards, and reduce losses every quarter. Consider partnering with a consulting

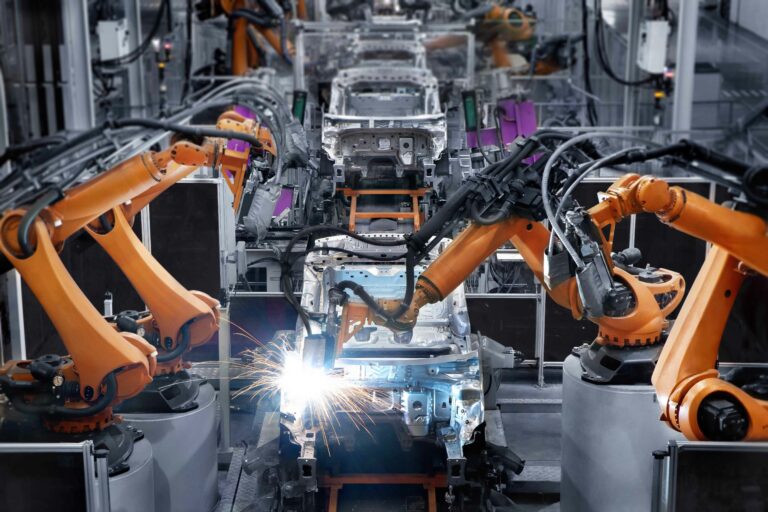

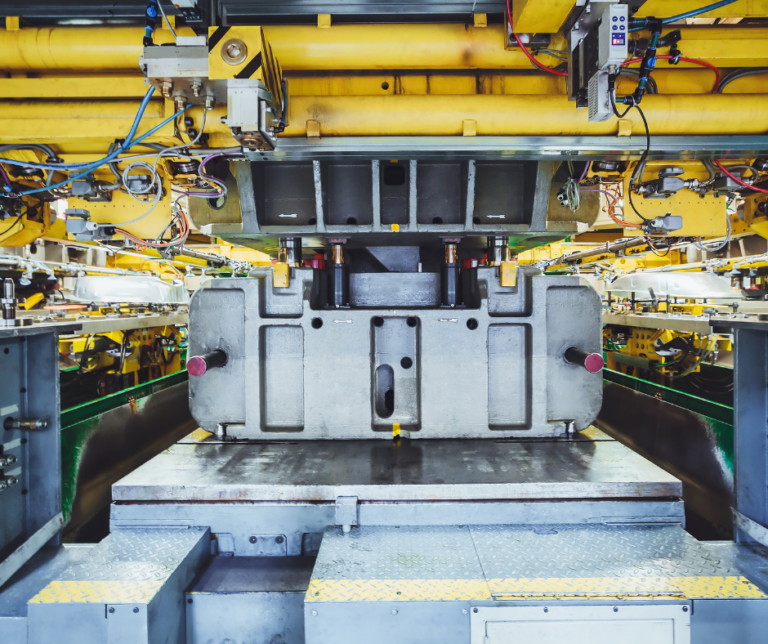

The implementation of process control methods is still in the beginning stages within the traditional automotive stamping environment. Many stamping organizations struggle to maintain consistent

Hiring is difficult. Hiring for highly skilled technical positions like quality engineers is even more challenging. Unless you have a great network of qualified individuals, you’ll

WHAT IS PROCESS IMPROVEMENT? According to Business Dictionary, process improvement is “Systematic approach to closing of process or system performance gaps through streamlining and cycle time

WHAT IS FORMABILITY SYSTEMS IMPROVEMENT? Formability systems improvement is the analysis and optimization of formability processes in manufacturing, such as tool and die, sheet metal

There is currently a labor and skills shortage in the tool and die trade which will impact the future of manufacturing. Like many disciplines, even

LEARN WHY THE RPA PROCESS IS USED SO FREQUENTLY BY TOP MANUFACTURERS AROUND THE GLOBE WHAT IS THE RAPID PLANT ASSESSMENT PROCESS? The Rapid Plant

HOW THE MANUFACTURING INDUSTRY CAN MANAGE CHALLENGES BROUGHT ON BY TRADE TARIFFS WHAT ARE YOUR OPTIONS FOR DEALING WITH TRADE TARIFFS? If you work in

In 2020, the automotive tooling spend is almost one-third below the total from 2019. What does this mean? For starters, one of the main reasons

We are a team of technical professionals who work shoulder to shoulder with you to help improve processes and products.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Phasellus hendrerit. Pellentesque aliquet nibh nec urna. In nisi neque, aliquet vel, dapibus id, mattis vel, nisi. Sed pretium, ligula sollicitudin laoreet viverra, tortor libero sodales leo, eget blandit nunc tortor eu nibh. Nullam mollis. Ut justo. Suspendisse potenti.

Sed egestas, ante et vulputate volutpat, eros pede semper est, vitae luctus metus libero eu augue. Morbi purus libero, faucibus adipiscing, commodo quis, gravida id, est. Sed lectus. Praesent elementum hendrerit tortor. Sed semper lorem at felis. Vestibulum volutpat, lacus a ultrices sagittis, mi neque euismod dui, eu pulvinar nunc sapien ornare nisl. Phasellus pede arcu, dapibus eu, fermentum et, dapibus sed, urna.

Morbi interdum mollis sapien. Sed ac risus. Phasellus lacinia, magna a ullamcorper laoreet, lectus arcu pulvinar risus, vitae facilisis libero dolor a purus. Sed vel lacus. Mauris nibh felis, adipiscing varius, adipiscing in, lacinia vel, tellus. Suspendisse ac urna. Etiam pellentesque mauris ut lectus. Nunc tellus ante, mattis eget, gravida vitae, ultricies ac, leo. Integer leo pede, ornare a, lacinia eu, vulputate vel, nisl.