Your highest priority is making customer shipments daily, which immediately prioritizes press line productivity. Your focus is how to make a press run faster and more frequently. There is nothing wrong with addressing productivity at the press line, as long as you don’t stop there. A poorly defined die shop management system—including die maintenance and repair processes—can dramatically decrease press line productivity and increase costs.

What Is Die Maintenance?

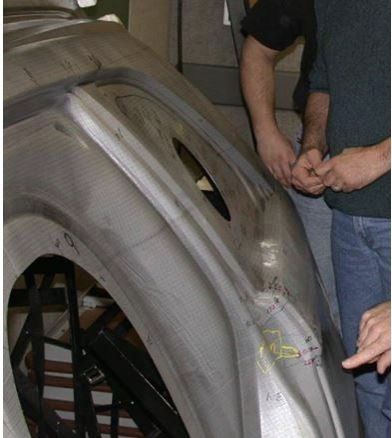

Die maintenance refers to the systematic process of inspecting, repairing, and optimizing dies used in manufacturing processes. Die maintenance involves routine inspections to identify wear, damage, or defects, followed by necessary repairs and adjustments. Preventive maintenance is also a key aspect, aiming to address potential issues before they cause disruptions to production.

Benefits of Preventative Die Maintenance

- Improved equipment and system reliability

- Reduction of unexpected breakdown

- Decrease in expensive parts replacement

- Extended equipment life

- Better parts inventory management

The Cost of Poor Die Maintenance

Poor die maintenance causes quality defects during production, driving up sorting costs, increasing the likelihood of shipping defective parts to the customer, and risking expensive forced containments. Additional cost for scrap is visible. With the current logistical problems, we may even run our supplier out of material and be unable to meet your shipping obligations. Quality defects can force production runs to be cut short, leaving little time for effective die repair. Poor quality is expensive.

Lost press time while making temporary modifications “under the ram” is costly too. And there is more: subpar die changes under ram must be permanently corrected before the next production run, doubling the maintenance costs and potentially more lost press time.

If we are lucky, that buckle or split we were trying to fix has temporarily disappeared, but new variation has been introduced to the part. Assembly must alter fixtures, clamping, and robotics to compensate for this variation. And after all that, assembly will have to reverse all the changes made as permanent die corrections are implemented. Creating a robust die shop management system will decrease visible and invisible costs at the press line, shipping, and assembly before they occur.

Streamlining Die Repair & Maintenance Tasks

Leading manufacturing theories used daily by production are not commonly applied to your die shop management system. If you can correctly implement them, you can reduce die repair turnaround and inventory (number of dies at repair) and improve the quality of the repair. The critical path to streamline die repair tasks, root cause analysis to guarantee we fix the actual problem, and standardizing work for ease of training and quality of repair are just a few examples.

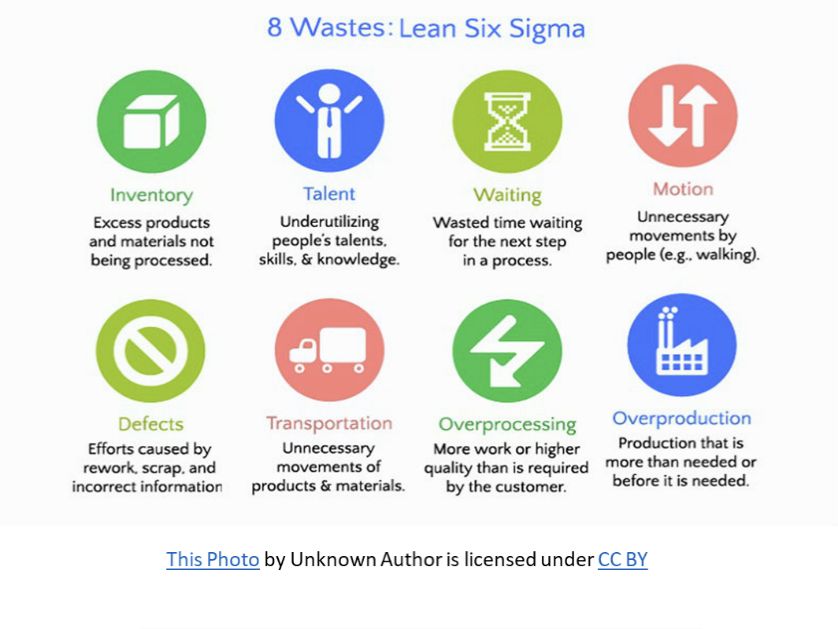

When applying Lean tools to your die shop maintenance system, it can be difficult to adapt the tool, so it has the desired impact. For example, you cannot take your single-piece-flow process at a transfer line and implement it in your die maintenance area. But we can use single-piece flow principles to improve the die repair flow through the repair area, jump-starting the value-added repair work and increasing die repair throughput.

Doing the Right Work, on the Right Die, at the Right Time

If, during a production run, a die experiences severe wear or is damaged, to a level that the production process cannot make adjustments to finish the necessary part count, that die is going to go from the press bolster directly to the die shop for repair.

Another common way that die repair and preventative maintenance is prioritized is:

There is an open workspace in the die shop, and the die hanging on the crane, just having finished a complete production run, has an open work order. Other die sets may have more demanding repairs, or those repairs may risk of changing the part quality, so these become convenient excuses to “not have to be doubled handle” by storing the die that just came out of the press and moving a die that should have a higher “repair Priority,” into the open die shop workspace.

Phoenix has always professed a need for a controlled process within the Stamping industry. The die, its part touching surfaces, alignment mechanisms, die component and part locating details, the sheet metal restraining and pressure generating surface are all a considerable part of that process needing to be controlled and, if necessary, returned to their original working condition.

Allocating the skilled trade resources now available to maintain the dies is a subset of the overall “process control” dynamic, used to establish tool and die priorities and is sometimes referred to as a decision tree.

Using the Decision Tree to Establish Tool & Die Priorities

Issue:

There is a need for a systematic, data-based approach to determine what dies will be worked on and when the work will be done. These decisions should be based on production needs, customer satisfaction, and return on investment.

Solution:

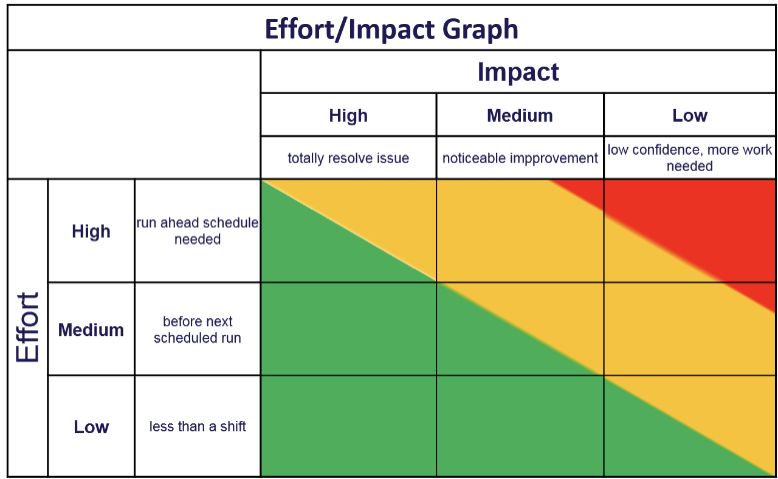

Using the tool and die decision tree will enable die shop management to prioritize open work orders. Using the prioritized work orders, working leaders or die makers can decide on work (Self)-assignments. Based on available manpower and skill level, time until that die line needs to produce parts again, available floor space in the work area, if the necessary equipment is available, etc.

The highest priority for the decision tree is if a No Build part condition exists due to the press shop not being able to run production because of broken dies, quality rejection figures making the part unprofitable to produce, and formal customer quality complaints.

The next priority level of the decision tree is if Production through-put or Quality Improvement is Needed because of higher than desired part quality rejection figures, informal customer quality complaints, or if formability issues produce random part failures.

The next step down in priorities is continuous improvement to eliminate marginal formability strain status and incorporate material savings or engineering changes.

Example of How the Tool & Die Decision Tree Functions:

A particular die has an open work order resulting from a Quality Alert Bulletin (QAB), and another resulting from a formability issue. The QAB work order requires two shifts to complete, while the formability work order needs only four hours. The Die Group Leader determines that there is only one shift available, so the formability work is completed, leaving the QAB work open for the next opportunity. Alternatively, if only two shifts are available, a release could be requested to perform the QAB work on the two shifts and leave the formability work order open.

A good priority system improves the effectiveness of the entire department, but without priorities, less meaningful work is accomplished. The truly meaningful work didn’t get scheduled because I wasn’t informed it needed to be done – -so it wasn’t my job, – – and nobody is at fault – – but everybody gets blamed when the part quality is low.

The Value of Work Order Systems in Die Maintenance & Repair

Request for die work comes from many different sources, such as:

- Quality complaints line-side or from the body shop

- A comparison of the current production panel and the reference panel shows differences in draw-in or impact lines.

- Preventive maintenance activities uncovering die surface erosion or an engineering change request.

The work order system allows an organization to document, track, prioritize, and schedule all die repair or maintenance activities. The system is best used as a communication tool, identifying the root problem, the steps to correct the problem, and a place to detail any unfulfilled basic conditions that were corrected. A completed work order should document what the agreed upon die work performed was intended to accomplish and provide a means to track reoccurrences of the issue in the future.

If a die set reveals multiple areas that require attention, creating die work requests provides the scheduling department with information to prioritize the work according to:

- Available time between runs (will a production run ahead be necessary?)

- Amount of effort compared to the value of the improvement.

- Documentation of previous repair history (is this a recurring, high-wear area?)

- In reviewing work history and considering new work orders, we should always determine if previous repairs resulted in unintended consequences, negatively affecting die robustness.

If the necessary work cannot be completed in the typical time before the set of dies returns to production, we need to determine the number of die cycles that will be missed to complete the work order. This data will aid in determining if extra racks and/or additional part storage space will be required. If the facility cannot provide the racks or floor space, the decision to proceed may require that the repair/correction be performed in a series of steps. This will require detailed recommendations defining the specific work that is to be completed between each production run while documenting the portion of the work plan that was completed in order to schedule subsequent die repairs to finish the work order.

Data from previous work orders can also be utilized to improve preventative maintenance plans and scheduling on symmetrical parts or non-identical parts within the part families (fenders, inner or outer doors, hoods, roofs, etc.).

Work orders that resolve formability issues need to be shared with Engineering (feedback process) to prevent similar issues from re-appearing on consecutive product designs (a traditional problem—one that shows up model after model). Our hope is that providing part of the performance history (including the frequency of occurrences), work required, and the impact of those changes on performance will help create a library or history of best practices to improve the necessary responses in the future.

Optimize Die Maintenance With Help From Phoenix

Optimizing die maintenance is integral to overall manufacturing efficiency. By applying production theories, utilizing decision trees for prioritization, and implementing effective work order systems, manufacturers can ensure the right work is done at the right time, leading to improved productivity and reduced costs.

Partnering with an organization like Phoenix could be the difference between knowing a good idea and making fundamental changes. If you’re interested in learning how The Phoenix Group can drive improvement at all levels of your organization, contact us today.