The Phoenix Group Welcomes Professor Menachem Kimchi

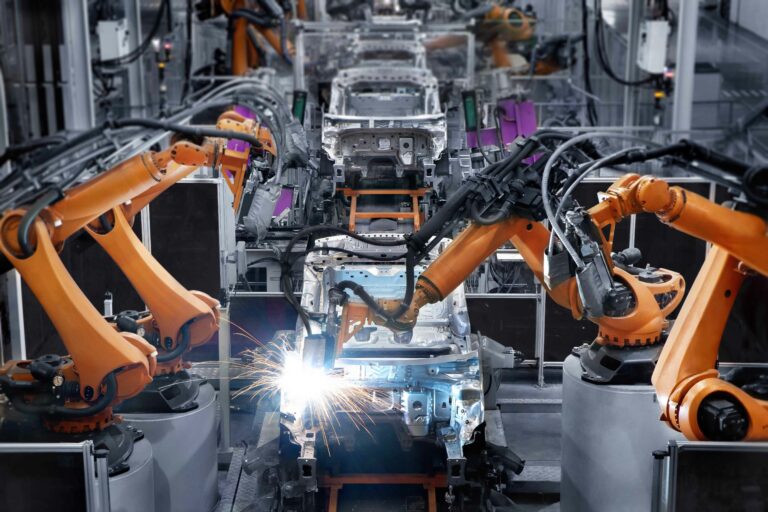

The Phoenix Group has worked for many years with Professor Menachem Kimchi from The Ohio State University on the development of welding / joining principles

The Phoenix Group has worked for many years with Professor Menachem Kimchi from The Ohio State University on the development of welding / joining principles

In the manufacturing sector, for many years, we have heard the debate over quality vs. quantity. It usually sounds something like this: “The boss has to

If you’re in the automotive industry, chances are by now you’ve heard of IATF 16949. This is something that’s on everyone in the automotive supply chain’s

The goal of engaging with a process optimization consulting service is to drive lasting change. This won’t happen if the measures implemented by the organization

Running a manufacturing plant is difficult. You must manage multiple stakeholders, drive continual improvement while maintaining safety standards, and reduce losses every quarter. Consider partnering with a consulting

The implementation of process control methods is still in the beginning stages within the traditional automotive stamping environment. Many stamping organizations struggle to maintain consistent

Hiring is difficult. Hiring for highly skilled technical positions like quality engineers is even more challenging. Unless you have a great network of qualified individuals, you’ll

WHAT IS PROCESS IMPROVEMENT? According to Business Dictionary, process improvement is “Systematic approach to closing of process or system performance gaps through streamlining and cycle time

WHAT IS FORMABILITY SYSTEMS IMPROVEMENT? Formability systems improvement is the analysis and optimization of formability processes in manufacturing, such as tool and die, sheet metal

There is currently a labor and skills shortage in the tool and die trade which will impact the future of manufacturing. Like many disciplines, even

We are a team of technical professionals who work shoulder to shoulder with you to help improve processes and products.