Companies around the world use many different types of sheet metal to produce their products. When designers and engineers are trying to decide which material to use to meet the desired attributes for their product, they are considering many different characteristics, or mechanical properties.

What Are Mechanical Properties?

Mechanical properties are used to identify and classify materials. They are properties that involve a material’s reaction to an applied load.

The Importance of Mechanical Properties

Some parts need strength to withstand forces or pressures, some are light weight to be efficient, but all need to meet the formability requirements of a stable product design. One of the key components to proper selection, and process capability is understanding the Sheet Metals Mechanical properties. This leads us to two main questions; how can we get those mechanical properties? what does each mechanical property mean?

How to Determine the Mechanical Properties of Materials

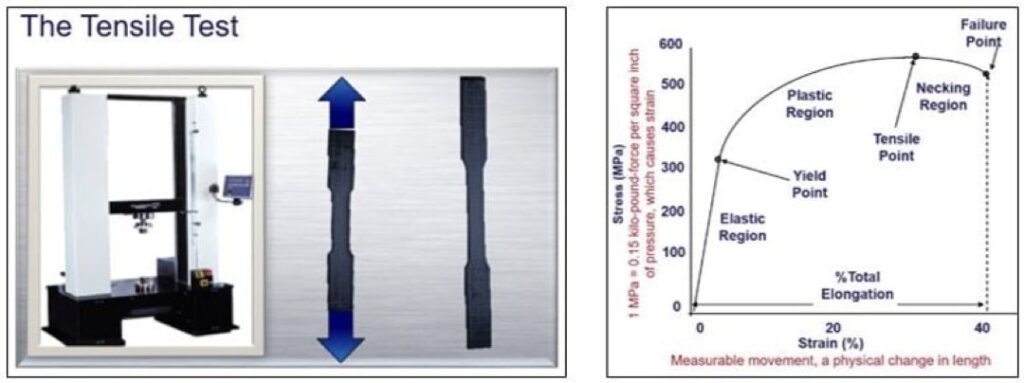

To respond to those questions, let’s start talking about the tensile test. The tensile test is a standardized method to determine the materials mechanical properties.

This method is performed by holding a sample, called specimen, in a rigid device and increasing the load or the stress applied to pulling on the sample until failure occurs. During this process, we record how much stress, or pulling force is being applied to the material, and what shape changes are occurring to the specimen. The shape changes we are looking for are length (elongation) and thickness of the material. The output information is plotted in graphical form and is referred to as the stress-strain diagram. Most of the key mechanical properties come from the tensile test.

Material Mechanical Properties

The most used mechanical properties determined during the tensile test are:

Yield Strength

The YS is a measure of a material’s elasticity, this shows the highest stress that can be applied to a material prior to permanent (plastic) deformation, in other words it is where the elastic deformation ends, and the plastic deformation begins.

Tensile Strength

The TS is the maximum amount of stress a material incurs prior to failure; it also defines the onset of necking.

Total Elongation

The TE is a percentage by which a material can be stretched before it breaks, usually expressed as a percentage over a fixed gauge. Ductility is often reported as % elongation, which is also a rough indicator of formability (a higher number indicates improved formability).

N -Value

The N Value is also known as strain hardening exponent; it indicates the relative stretch formability of sheet metals and the increase in strength due to plastic deformation. Measured as the slope of the true stress – strain curve generally between 10-20% strain. A higher number indicates better ability to reduce concentrated strain by redistributing the strain over a larger area.

R- Value

The R Value, sometimes referred to as the plastic strain ratio; indicates the ability of a sheet metal to resist thinning or thickening. A higher number indicates better drawability.

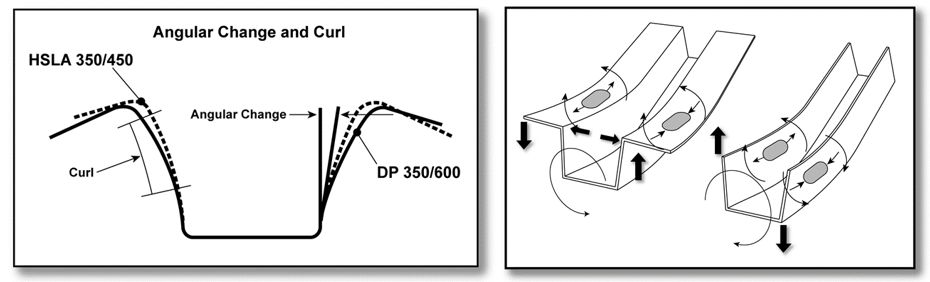

Optimizing Material Performance: Mitigating Springback Challenges

The relaxation of the atomic spacing and residual stress, or springback, in sheet metal causes the stamped part to react in three distinct ways. The part can twist, sidewalls and flanges endure angular changes, and sidewalls can curl. The twisting of the part is due to an unbalanced strain pattern either in the sidewall or flange, or in some cases both. The stresses in the stamping create a torsion effect and the part reacts to the torsion by twisting. Sidewalls and flanges change angularly, typically due to the thickness change that occurs as the metal moves over the forming radius. This thickness reduction coupled with varying strain levels throughout the wall depth creates a tension effect causing the wall and/or flange angle to change. Sidewall curl is a result of an uneven strain gradient that occurs during the bending and straightening of the material as it moves over the draw radius. These strain gradients will be different along the height of the wall, creating a curvature in the stamping.

Die designers compensate the geometry of the die to correct or stabilize the part dimensionally. Some designers add stiffeners down the height of the wall or small stiffener beads in the radius to lock in stresses at a given point of the part geometry. Changes in the forming process will affect the residual stresses in the stamped part and dimensional deviation may accrue. These dimensional changes may not meet quality standard or cause assembly issues further into the joining operations. Changes in lube reapply or blank wash roll pressures will have a dramatic effect on the strain patterns in the stamping. An increase of lube can lessen the amount of plastic deformation in the part resulting in an angular change in the sidewall or even the twist in the stamping. Do not rely on the restrike operation to correct springback changes in the initial forming operation, advanced high strength steel will not react the same as mild steel.

The higher cost of advanced high strength steel and an undisciplined process can result in large losses due to scrap and rework. Creating a press and die recipe to follow during the stamping operation is highly recommended. Process control is critical to replicating a quality stamping and minimizing the losses due to scrap or rework. The recommendations are to perform a formability analysis and dimensional check of the part to identify strain levels and dimensional accuracy. The use of templates to check draw lines and measurements of draw in amounts help monitor consistency of the stampings.

Need Help Understanding Mechanical Properties of Engineering Materials? The Phoenix Group has you covered!

A good understanding and use of these mechanical properties are very important and beneficial to the manufacturing industry. These mechanical properties will allow engineers to predict failures, behaviors and tendencies of metals during the forming processes and can aid in the decision-making process for material selection by quantifying the information.

If you’re interested in learning how The Phoenix Group can help your company, contact us today.