What Are Advanced High-Strength Steels (AHSS)?

Advanced high strength steels (AHSS) are stronger and more complex than the mild steels being used today. Understanding how these steels react during the forming process helps stamping and component manufacturers make better decisions regarding the selection of fabricating equipment. Failure to understand a steel’s global and local formability performance can result in lost production time, component rework and additional die repair.

Key Differences Between Mild Steel & Advanced High-Strength Steels (AHSS)

Some of the key differences between mild steel and advanced high strength steels are in their chemistry, thermal mechanical processing, and microstructures, all leading to profound differences in forming behavior. Mild steel consists mostly of a single phase of ferrite, with various amounts of pearlite based on the percentage of carbon in the steel. They are characterized by low strength and excellent formability. Strength is achieved by a mechanism known as solid solution hardening. In comparison, high strength, low alloy steels (HSLA) achieve greater strength via higher concentration of carbon and the introduction of other alloying elements, such as manganese and silicon. Improvements in strength are offset by reductions in formability.

The Chemical Compounds of Advanced High-Strength Steels (AHSS)

Advanced high strength steels are primarily steels with a microstructure containing a phase or constituent in addition to ferrite in quantities sufficient to produce unique mechanical properties. These include martensite, bainite, austenite and/or retained austenite.

Some types of AHSS have a higher strain hardening capacity resulting in a strength-ductility balance superior to conventional steels. Other types have ultra-high yield and tensile strengths and show a bake hardening behavior.

Types of Advanced High-Strength Steels (AHSS)

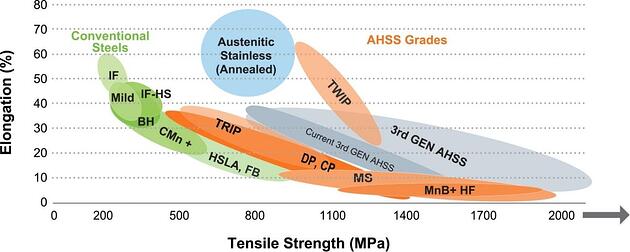

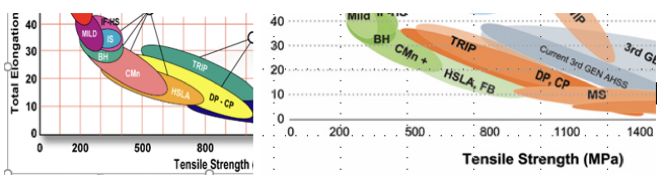

The various product families of AHSS are shown below in the Steel Strength – Ductility Diagram. Each ellipsoid represents the various strength and ductility combinations available within the product family.

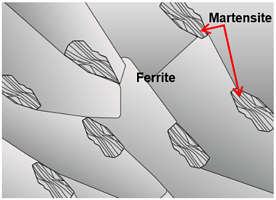

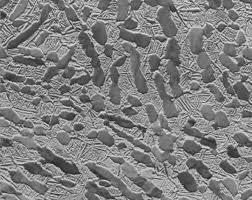

Dual Phase steel is perhaps the most popular type of AHSS found today in body structures and components. These steels contain phases of both Ferrite and Martensite. The level of martensite and strength is directly related to the carbon concentration, but both phases are stable at room temperature via thermal-mechanical processing in the steel mill. The following micrograph and schematic show a dual phase microstructure.

Transformation Induced Plasticity or TRIP steels have multiple phases – Ferrite, Martensite, Retained Austenite and Bainite. During the work hardening of TRIP Steels, the retained austenite transforms to martensite, achieving very high strength in the final part. Formability decreases compared to a mild steel, but increases compared to HSLA steels.

Advanced High-Strength Steel Applications: AHSS in Practice

Product development in steel research centers has been aimed at creating stronger steels that allow vehicle crash regulations to be met, while also enabling thickness reduction for light-weighting. Weight reduction improves vehicle efficiency, important as vehicle manufacturers struggle to meet stiffening regulations for increasing fuel economy and reduced greenhouse gas emissions. At the same time, new steels must be formable to produce the complex geometries in today’s vehicle designs.

With AHSS, we find higher forming forces are required – this translates into:

- Higher press loads

- Higher blankholder and punch forces

- Accelerated die wear, requiring special die materials and surface treatments

- The potential for greater springback and part distortion

- Revised trim and cutting practices

- The use of temperature resistant lubricants

New analysis tools are being used to understand edge cracking, stretch bending limits, and instantaneous work hardening exponents. The result of the analysis has helped engineers understand the design limits of AHSS. Properly educating and training the individuals that will be required to perform process and die maintenance will greatly increase production robustness and manufacturing success.

Maximizing Impact: AHSS vs HSLA in Vehicle Manufacturing

Properly selected AHSS steel alloys can do more than just:

- Reduce mass.

- Improve fuel economy.

- Enhance crash survivability.

A properly engineered die, designed to take advantage of AHSS material formability properties, will provide a robust die whose geometry would not be producible if a traditional HSLA, with similar Yield strength and terminal “N” value were substituted.

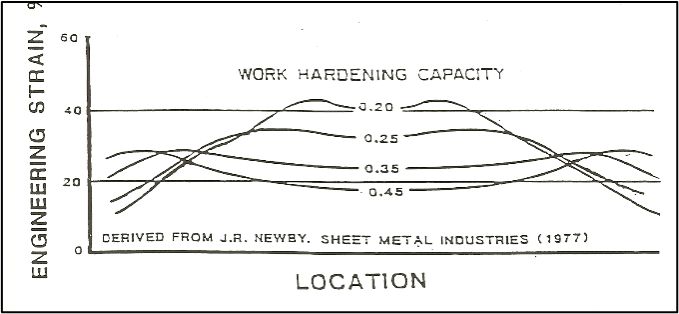

Understanding the N-Value

Strain distribution in a hemispheric dome test of various steels reveals that when the n-value increases, the distribution of strains at high stress locations becomes more evenly distributed. The strain distribution in the above graph shows this effect. The common n-value for the following steels: Mild steel (0.02), IF steel (0.25), stainless steel 3XX (0.35, 0.45). This graph shows the control the n-value has over the distribution of strain. HSLA steels have n-values less than 0.20.

Steel Strength Ductility Diagram (SSDD)

The Steel Strength Ductility Diagram (SSDD) has gone through several revisions to reflect the developments of the designer steels currently available. Through enhanced steel processing refinements, HSLA materials show a potential 25% increase in tensile strength (800 MPa to 1000Mpa), but those material’s total elongation capabilities remain below 30%. First generation Dual Phase materials capabilities show they originally had substantially better tensile strength and elongation properties and those mechanical properties continue to improve with current third generation AHSS production developments.

Formability Differences

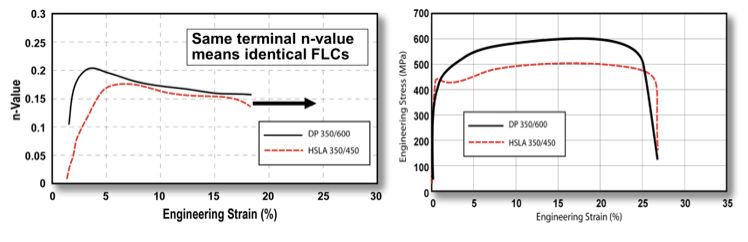

The two charts above compare formability differences of a DP and HSLA of the same YS. The difference in instantaneous n-value is measured and plotted as a function of engineering strain n-value and its formability effect (is graphed on the left). The largest n-value increase occurs around 3% strain and drops back to the HSLA curve around 7%. The plotted instantaneous n-value graphically displays the early formability enhancement which would not be noticed in the traditional n-value calculation. Beyond 7% the two plot lines become virtually parallel and would have the same traditional n-value (10% to 20% or to UTS if lower) for calculating the Forming Limit Diagram plain strain value. The benefit of this early work hardening is an early distribution of the initial strains and a reduction or elimination of highly localized strain gradients.

Forming Limit Curve (FLC) Insights

- Deformation of DP steels changes the n-value.

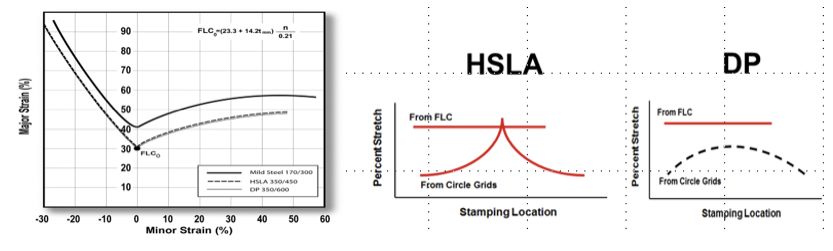

The Forming Limit Curve is based on the sheet thickness and the terminal n-value. Having the same terminal values, the HSLA and DP 350/xxx steels have the same terminal n-values and thus the same FLD0. (See the left hand FLD graph below).

- Traditional FLC’s do not show the benefits of DP steels that work harden in very low strain conditions.

The early initial increase in the n-value for the DP steel caused the redistribution of the forming forces and the CGA strain pair readings would plot further away from the FLC failure line.

This redistribution of stress, (same part geometry but substituting AHSS for HSLA blank material), is shown in the center and right-hand images below.

It should be noted that HSLA is susceptible to severe stretch gradients and has a low FLC value.

Dual Phase materials have an improved capability to resist those severe gradients but have a similarly low FLC value. DP materials increased stretchability is the result of early in the part forming, (motion of the press and die), DP’s ability to distribute rather than focus stress. Once stretched to 3% (and up to about 7%) the DP requires increased stress, in that work hardened area, to strain more, (elongate further). The material required to satisfy the increased part shape (length of line), is created from adjoining areas that have not been work hardened to the same degree yet, (strain distribution). This increase in formability between comparable AHSS and HSLA, materials is visually seen in the early separation of stress/strain diagrams that results from that early work hardening.

The more uniform the strain distribution(s), the less likely slight process input variation, will result in significant differences in the formed part.

Contact Phoenix for Manufacturing Success with Advanced-High Strength Steels

Want to learn how The Phoenix Group helped General Motors drive 50% reduction in metal scrap and 35% throughput improvement? Click the link below.

If you’re interested in learning how The Phoenix Group can help your company, contact us today.