Formability analysis is a crucial aspect of material engineering, especially in industries like automotive manufacturing. This process involves various techniques such as circle grid analysis and thickness strain analysis, aimed at assessing how materials behave during forming processes.

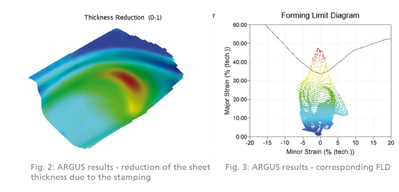

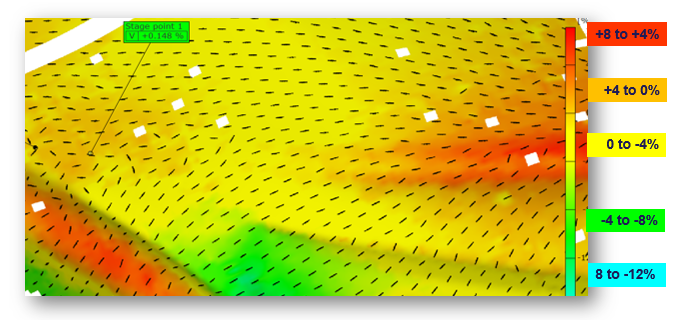

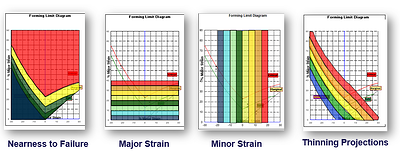

Analyzing a sheet metal stamping for nearness to failure is one of the key parts of the formability system. The measured strain (Major and Minor), and the amount of thickness reduction tells us how robust our stamping process is. Plotting the measured strain against the Forming Limit Curve and determining the distance to failure allows us to quantify the amount of variation the process can handle. The use of the Argus system to measure surface strain, calculate thickness reduction, visually display 3D stain models, re-calculate the strain measured from the surface and project it to the center of the sheet, and create forming limit diagrams are just a few of the outputs the system can produce.

Exploring Circle Grid Analysis

Circle grid analysis is a fundamental method used in formability analysis. It involves etching circles onto a blank, which is then formed into a specific shape. As the material undergoes deformation, these circles transform into ellipsoids, providing insights into deformation modes and strain extents.

Enhancing Precision with Circle Grid Analysis Stamping

In modern manufacturing, circle grid analysis has evolved with the introduction of automated and camera-based systems. This advancement enhances precision and efficiency in assessing material formability. Additionally, timestamping data during circle grid analysis is essential to track changes over time and account for material property variations.

Leveraging Circle Grid Analysis Equipment

Advanced high-strength steels are primarily steels with a microstructure containing a phase or constituent in addition to ferrite in quantities sufficient to produce unique mechanical properties. These include martensite, bainite, austenite, and/or retained austenite.

Some types of AHSS have a higher strain hardening capacity resulting in a strength-ductility balance superior to conventional steels. Other types have ultra-high yield and tensile strengths and can show a bake-hardening behavior.

Understanding Formability Limit Diagrams

Formability limit diagrams, also known as forming limit curves, play a pivotal role in formability analysis. By charting the extent of strain against these diagrams, engineers can assess the nearness to failure of materials. This aids in troubleshooting manufacturing processes and identifying potential issues in formed parts.

Insight into Circle Grid Strain Analysis

Circle grid strain analysis provides valuable information about the strain distribution within formed parts. Engineers can identify areas of concern, such as wrinkles or strains, and make informed decisions to optimize manufacturing processes.

In conclusion, formability analysis, including circle grid analysis and other techniques, is essential for ensuring the efficiency, safety, and stability of manufacturing processes. By leveraging advanced methodologies and equipment, engineers can drive innovation and progress in material engineering, ultimately benefiting various industries.

Contact Phoenix for Formability Analysis & Success

Our skilled team of formability analysts solve your complex forming problems. Formability is a core competency at The Phoenix Group. Our comprehensive solutions cover the gamut of the Tool and Die Maintenance Operating System, from the Formability Lab to the Press lines and Die Shop.

If you’re interested in learning how The Phoenix Group can help your company, contact us today.